Few things are more expensive to today’s manufacturer than downtime caused by worn out or broken parts. Diamond Coatings Australia thin film coating is your number one defense against costly downtime caused by part failure, and it is environmentally friendly.

Combining the extreme hardness of diamond coating with the flexibility and lubricity of silicon carbide, Diamond Coatings Australia coatings offers the ideal solution for situations where extreme mechanical forces, chemical corrosion or other degrading factors cause failures that traditional protective coatings cannot overcome. This can be done without the use of environmentally harmful chrome, nickel or other heavy metals.

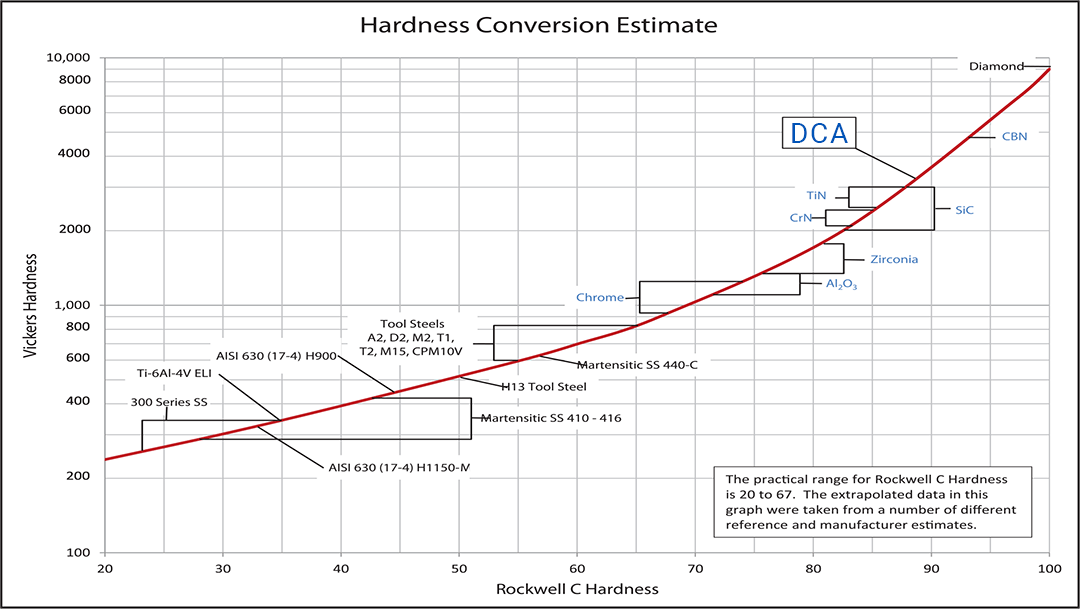

Diamond Coatings Australia thin film coatings are characterized by extreme hardness, lubricity, high wear resistance and high corrosion resistance.

The coating is deposited by a proprietary plasma- assisted chemical vapor deposition (PACVD) process that evenly coats three dimensional objects without rotation or multi-step processes. Build up at edges or corners is essentially immeasurable. The coating can be applied thoroughly and evenly to the most intricate and/or the most massive parts to dramatically extend their lifetime.

Far different from the diamond-like and carbide thin films familiar to the coating industry, DCA films are created from layers of nano-crystalline carbide in an amorphous matrix.

This unique combination of layers and phases of carbide give DCA films a wide range of properties, and extremes in those properties, only surpassed by pure diamond.

Applications are broad and range from subsea oil exploration at 20,000 ft to aircraft flying at 40,000 ft, from sour gas to human blood, and from Artic Poles to deserts. Wherever they are used, these coatings exceed designers’ expectations.

| Hardness | ≥ 17 GPa (≥ 85 Rc) |

| Lubricity | Significant reduction in coefficient of friction lab tests and required torque in field applications as compared to bare metal. 50% or greater friction reduction with no lubrication as compared to bare metal is typical. |

| Wear Rate | Significant reduction |

| Flexural Strength | Can withstand > 46,000 psi tensile and compressive stresses and compressive strain of 0 .17%. |

| Corrosion Resistance | Protects underlying substrate from most corrosive agents. |

| Conformal to Substrate | Plasma-assisted CVD by definition deposits evenly over all surfaces of a part without special fixturing or rotation. |

| Operating Temperature | - 200°C/-320°F to > 600°C/1112°F (dependent on oxygen partial pressure) |

| Thermal Conductivity | 10 W/cm °K |

| Electrical Resistivity | > 109 ohm em (doping options to lower p) |

| Colour | Gray / Black |

For general enquiries, please use the options below.